- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

- Place of Origin: XI'AN

- Brand Name: Xi an aerospace pumps Company limited

- Model Number: DY

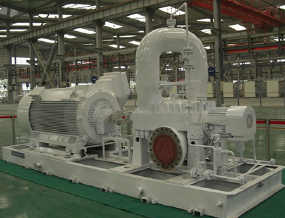

DY series oil transfer pump Introduction

Xi'an Aerospace Pump Company is specialized in producing all kinds of centrifugal oil transfer pump manufacturer, has cooperate with Sinopec and CNPC to develop a variety of oil transfer pump, in part to replace the imported products. At present, existing series of products, and can develop, produce all kinds of high-end centrifugal pumps according to customer needs

Performance range

Capacity (Q):50 ~1000m3/h(the capacity of SDY type pump can reach to 1700 m3/h )

Head (H):100 ~1500m

Working pressure(P):15MPa

Structure and characteristics:

1、

DY type pump is horizontal split, single-suction, multi-stage centrifugal pump, impellers arranged symmetrically back to back, the axial force basic balance structure. Interstage connection adopt internal flowpath and external transition flow.

2、

SDY type pump for horizontal split, double suction first-stage, multi-stage centrifugal pump, impellers arranged symmetrically back to back, the axial force balance structure.

3、

Full three-dimensional design (CAD) combined with advanced flow field analysis (CFD) and strength analysis (CAE), the pump's reasonable structure, small size and high efficiency design goals.

4、

Rotor parts adopt easy assembly structure, pump disassembly without special tools, the high strength stud between uper and lower pump body was densely design by the 3D simulation optimization to ensure smooth operation of the pump under high pressure, and ensure the open face no leakage.

5、

Inlet and outlet flanges of pump on both sides of pump body, horizontal layout, easy assembly and disassembly.

6、

Volute arranged symmetrically with each other by 180 ° balance furthest radial force, the rotor section has go through rigorous balancing test, ensure that the pump for a long time efficient and smooth operation.

7、

Cartridge mechanical seal structure to ensure reliable sealing, installation and maintenance more convenient. Pipeline of flush seal the hydrocyclone may be provided on flush sesl pipeline , to ensure the cleanliness of the sealing fluid, prolong seal life.

8、

Pump rotor can be supported by rolling ball bearing, also can be supported by bush(ing) bearing.When being supported by bush(ing) bearing, the residue axial force of pump is born by the thrust bearing in the non-driven-end bearing parts.Bearing can adopt self-lubricating or forced feed lubrication mode as required, satisfies the requirement of heavy load high-speed cruising.

9、

Product design meets U.S. API 610 standards, through the authentication of ISO9001 quality certification system.

10、

Turning of pump: see pump from motor direction, pump is the clockwise direction rotation. According to user's needs, also can change turning of pump into counterclockwise rotation (adding " -L " in the pump type).

11、

According to user needs, DY pump can be configured to a variety of control sensors (temperature, leakage, vibration), to achieve remote monitoring.

Application:

It can be widely used in oil products, crude oil and other long-distance pipeline custody transfer, oil gathering stations, oil refinery, oil storage and terminal of each delivery and handling of crude oil, refined oil and residual oil, can also be used for conveying water and physical and chemical properties similar to water other liquids. Media viscosity ≤700mm2 / s, crude oil no containing solid particles, water and other products.

- Place of Origin: XI'AN

- Brand Name: Xi an aerospace pumps Company limited

- Model Number: DY

Examples of Application Engineering

输油泵产品主要应用情况表

The main applicable cases table of oil transfer pump product

NO. | Line name | Oil date | S type pump | DY type pump | SDY type pump |

1 | Kunda line | 2009/8/26 | 2 | 8 | |

2 | Liugui line | 2010/3/20 | 3 | ||

3 | Yangtianchong station | 2010/8/26 | 4 | ||

4 | Sunan line | 2010/11/1 | 8 | 8 | 2 |

5 | Beihai Nanning line | 2012/1/18 | 4 | 7 | |

6 | Daye station | 2011/8/15 | 2 | ||

7 | Yongshaojinqu | 2013/3 | 5 | 8 | |

8 | Hunan line | Installation Commissioning | 12 | ||

9 | Zhusanjiao | Installation Commissioning | 2 | 8 |

DY oil transfer pump series type

水平中开式离心油泵性能参数表(常温清水)

Horizontal split centrifugal pumps Performance parameters (the nomal temperature water)

Pump type | Capicity | Head | Speed | NPSHR | Pump Eff. |

m3/h | m | r/min | m | % | |

50DY100-HY | 50 | 100 | 2950 | 3.5 | 63 |

50DY200-HY | 200 | ||||

50DY300-HY | 300 | ||||

50DY400-HY | 400 | ||||

50DY500-HY | 500 | ||||

50DY600-HY | 600 | ||||

65DY200-HY | 65 | 200 | 2950 | 3.8 | 64 |

65DY300-HY | 300 | ||||

65DY400-HY | 400 | ||||

65DY500-HY | 500 | ||||

65DY600-HY | 600 | ||||

80DY120-HY | 80 | 120 | 2980 | 3.8 | 66 |

80DY180-HY | 180 | ||||

80DY240-HY | 240 | ||||

80DY300-HY | 300 | ||||

80DY360-HY | 360 | ||||

80DY420-HY | 420 | ||||

100DY120-HY | 100 | 120 | 2980 | 4 | 68 |

100DY180-HY | 180 | ||||

100DY240-HY | 240 | ||||

100DY300-HY | 300 | ||||

100DY360-HY | 360 | ||||

100DY420-HY | 420 | ||||

130DY160-HY | 130 | 160 | 2980 | 5.5 | 71 |

130DY240-HY | 240 | ||||

130DY300-HY | 300 |

Pump type | Capicity | Head | Speed | NPSHR | Pump Eff. | |||||

m3/h | m | r/min | m | % | ||||||

130DY400-HY | 130 | 400 | 2980 | 5.5 | 71 | |||||

130DY480-HY | 480 | |||||||||

130DY560-HY | 560 | |||||||||

130DY640-HY | 640 | |||||||||

155DY140-HY | 155 | 140 | 2980 | 5.5 | 71 | |||||

155DY210-HY | 210 | |||||||||

155DY280-HY | 280 | |||||||||

155DY350-HY | 350 | |||||||||

155DY420-HY | 420 | |||||||||

155DY490-HY | 490 | |||||||||

155DY560-HY | 560 | |||||||||

155DY630-HY | 630 | |||||||||

155DY760-HY | 760 | |||||||||

190DY160-HY | 190 | 160 | 2980 | 6 | 74 | |||||

190DY240-HY | 240 | |||||||||

190DY320-HY | 320 | |||||||||

190DY400-HY | 400 | |||||||||

190DY480-HY | 480 | |||||||||

190DY560-HY | 560 | |||||||||

190DY640-HY | 640 | |||||||||

190DY720-HY | 720 | |||||||||

220DY220-HY | 220 | 220 | 2980 | 10 | 75 | |||||

220DY330-HY | 330 | |||||||||

220DY440-HY | 440 | |||||||||

220DY550-HY | 550 | |||||||||

220DY660-HY | 660 | |||||||||

300SY60-HY | 300 | 60 | 1480 | 3 | 75 | |||||

300SDY120-HY | 120 | |||||||||

300DY200-HY | 200 | 2980 | 11 | 76 | ||||||

300SDY300-HY | 300 | 4 | ||||||||

300DY400-HY | 400 | 11 | ||||||||

300SDY500-HY | 500 | 4 | ||||||||

Pump type | Capicity | Head | Speed | NPSHR | Pump Eff. | |||||

m3/h | m | r/min | m | % | ||||||

300DY600-HY | 300 | 600 | 2980 | 11 | 76 | |||||

300SDY650-HY | 650 | 4 | ||||||||

300DY800-HY | 800 | 11 | ||||||||

310DY235-HY | 310 | 235 | 2980 | 12.5 | 76 | |||||

310DY470-HY | 470 | |||||||||

350SY60-HY | 350 | 60 | 1480 | 3 | 73 | |||||

350SY70-HY | 70 | |||||||||

350SY80-HY | 80 | |||||||||

350DY150-HY | 150 | 2980 | 13 | 80 | ||||||

350DY320-HY | 320 | |||||||||

350DY400-HY | 400 | |||||||||

350DY600-HY | 600 | |||||||||

350DY800-HY | 800 | |||||||||

400SY60-HY | 400 | 60 | 1480 | 2.5 | 75 | |||||

400SY70-HY | 70 | |||||||||

400SDY120-HY | 120 | |||||||||

400DY180-HY | 180 | 2980 | 13 | 80 | ||||||

400SDY270-HY | 270 | 5 | ||||||||

400DY320-HY | 320 | 13 | ||||||||

400SDY450-HY | 450 | 5 | ||||||||

400DY540-HY | 540 | 13 | ||||||||

400SDY630-HY | 630 | 5 | ||||||||

400DY720-HY | 720 | 13 | ||||||||

430SY60-HY | 430 | 60 | 1480 | 2.5 | 73 | |||||

430SY70-HY | 70 | |||||||||

430SY80-HY | 80 | |||||||||

430DY225-HY | 225 | 2980 | 18 | 78 | ||||||

430DY450-HY | 450 | |||||||||

430DY600-HY | 600 | 15 | 80 | |||||||

430DY800-HY | 800 | |||||||||

450SY60-HY | 450 | 60 | 1480 | 3 | 73 | |||||

450DY200-HY | 200 | 2980 | 13 | 80 | ||||||

Pump type | Capicity | Head | Speed | NPSHR | Pump Eff. | |||||

m3/h | m | r/min | m | % | ||||||

450DY400-HY | 450 | 400 | 2980 | 13 | 80 | |||||

450DY600-HY | 600 | |||||||||

450DY800-HY | 800 | |||||||||

450DY1000-HY | 1000 | |||||||||

500SY60-HY | 500 | 60 | 1480 | 3 | 75 | |||||

500SY70-HY | 70 | |||||||||

500SDY150-HY | 150 | |||||||||

500SDY220-HY | 220 | |||||||||

500DY240-HY | 500 | 240 | 2980 | 13 | 80 | |||||

500SDY360-HY | 360 | 5.5 | ||||||||

500DY480-HY | 480 | 13 | ||||||||

500SDY600-HY | 600 | 5.5 | ||||||||

500DY720-HY | 720 | 13 | ||||||||

600SY60-HY | 600 | 60 | 1480 | 3.5 | 77 | |||||

600SY70-HY | 70 | |||||||||

600SY110-HY | 110 | 2980 | 6 | 80 | ||||||

600DY240-HY | 240 | 14 | ||||||||

600SDY360-HY | 360 | 6 | ||||||||

600DY480-HY | 480 | 14 | ||||||||

600SDY600-HY | 600 | 6 | ||||||||

600DY720-HY | 720 | 14 | ||||||||

730SY60-HY | 730 | 60 | 1480 | 4 | 78 | |||||

730SY70-HY | 70 | |||||||||

730DY150-HY | 150 | 2980 | 14.5 | 80 | ||||||

730DY300-HY | 300 | |||||||||

730DY440-HY | 440 | |||||||||

730DY480-HY | 480 | |||||||||

860SY60-HY | 860 | 60 | 1480 | 4 | 81 | |||||

860SDY150-HY | 150 | 80 | ||||||||

860SY150-HY | 150 | 2980 | 12 | 80 | ||||||

860SY200-HY | 860 | 200 | ||||||||

860SY250-HY | 250 | |||||||||

Pump type | Capicity | Head | Speed | NPSHR | Pump Eff. | |||||

m3/h | m | r/min | m | % | ||||||

860DY300-HY | 860 | 300 | 2980 | 18 | 80 | |||||

860DY310-HY | 310 | 18 | ||||||||

860SDY450-HY | 450 | 12 | ||||||||

860DY600-HY | 600 | 18 | ||||||||

860SDY750-HY | 750 | 12 | ||||||||

1000SY70-HY | 1000 | 70 | 1480 | 4.5 | 82 | |||||

1000SY150-HY | 150 | 81 | ||||||||

1000SY200-HY | 200 | 2980 | 18 | 82 | ||||||

1000SDY300-HY | 300 | |||||||||

1000SDY400-HY | 400 | |||||||||

1200SY70-HY | 1200 | 70 | 1480 | 5 | 80 | |||||

1200SY80-HY | 80 | |||||||||

1200SY150-HY | 150 | 2980 | 18 | 82 | ||||||

1200SY200-HY | 200 | |||||||||

1200SY250-HY | 250 | 80 | ||||||||

1200SY300-HY | 300 | |||||||||

1200SDY400-HY | 400 | 82 | ||||||||

1200SDY500-HY | 500 | |||||||||

1500SY60-HY | 1500 | 60 | 1480 | 5.5 | 81 | |||||

1500SY70-HY | 70 | |||||||||

1500SY80-HY | 80 | |||||||||

1500SY90-HY | 90 | |||||||||

1500SY100-HY | 100 | |||||||||

1500SDY120-HY | 120 | |||||||||

1500SY120-HY | 120 | 2980 | 20 | 83 | ||||||

1500SDY150-HY | 150 | 1480 | 5.5 | 80 | ||||||

1500SY150-HY | 150 | 2980 | 20 | 83 | ||||||

1500SDY180-HY | 180 | 1480 | 5.5 | 80 | ||||||

1500SY180-HY | 180 | 2980 | 20 | 83 | ||||||

1500SDY220-HY | 220 | 1480 | 5 | 80 | ||||||

1500SY220-HY | 220 | 2980 | 20 | 83 | ||||||

1500SY250-HY | 250 | |||||||||

Pump type | Capicity | Head | Speed | NPSHR | Pump Eff. | |||||

m3/h | m | r/min | m | % | ||||||

1500SY300-HY | 1500 | 300 | 2980 | 20 | 83 | |||||

1700SY100-HY | 1700 | 100 | 1480 | 6 | 81 | |||||

1700SDY140-HY | 140 | |||||||||

1700SY140-HY | 140 | 2980 | 20 | 84 | ||||||

1700SY200-HY | 1700 | 200 | 2980 | 20 | 84 | |||||

1700SY270-HY | 270 | |||||||||

1700SY300-HY | 300 | |||||||||

1700SY340-HY | 340 | 83 | ||||||||

2000SY60-HY | 2000 | 60 | 980 | 5 | 83 | |||||

2000SY90-HY | 90 | |||||||||

2000SY120-HY | 120 | 2980 | 20 | 84 | ||||||

2000SY160-HY | 160 | |||||||||

2000SY230-HY | 230 | 83 | ||||||||

2000SY300-HY | 300 | |||||||||

2500SY65-HY | 2500 | 65 | 980 | 5 | 84 | |||||

2500SY80-HY | 80 | |||||||||

2500SY120-HY | 120 | 2980 | 25 | 84 | ||||||

2500SY150-HY | 150 | |||||||||

2500SY240-HY | 240 | |||||||||

2500SY320-HY | 320 | |||||||||

3500SY65-HY | 3500 | 65 | 740 | 5 | 81 | |||||

3500SY80-HY | 80 | |||||||||

3500SY120-HY | 120 | 2980 | 28 | 84 | ||||||

3500SY150-HY | 150 | |||||||||

3500SY240-HY | 240 | |||||||||

3500SY320-HY | 320 | |||||||||

5000SY65-HY | 5000 | 65 | 740 | 6.5 | 84 | |||||

5000SY80-HY | 80 | |||||||||

5000SY120-HY | 120 | 2980 | 35 | 84 | ||||||

5000SY150-HY | 150 | |||||||||

5000SY240-HY | 240 | |||||||||